Latest News

- 07 Oct 2025

DIGITAL TWIN – WITHOUT IT PROJECT

Only by automating highly repetitive manual activities such as inventory counting, ongoing stock management, triggering replenishment when demand arises, etc. can a granular Digital Twin emerge that enables you to act early without being dependent on human resources as a “bridge” between analogue and digital. Key challenge: The majority of companies are limited in time and budget to implement digitalisation projects, especially in the Internet of Things.

We help! With future-proof IoT solutions that connect hardware and smart devices – instead of firmly integrating them – only via semantic business logic to your materials management IT. This allows you to implement automation quickly, cost-effectively and flexibly in the future.

YOUR ADVANTAGE

Are you ready for the digital inventory monitoring of the future?

With the SMART INVENTORY MONITORING PLATFORM, you now have stock levels, consumption and material demands automatically under control thanks to smart technology. Sensors, readers, vending machines and smart systems that you no longer need to connect individually to your IT:

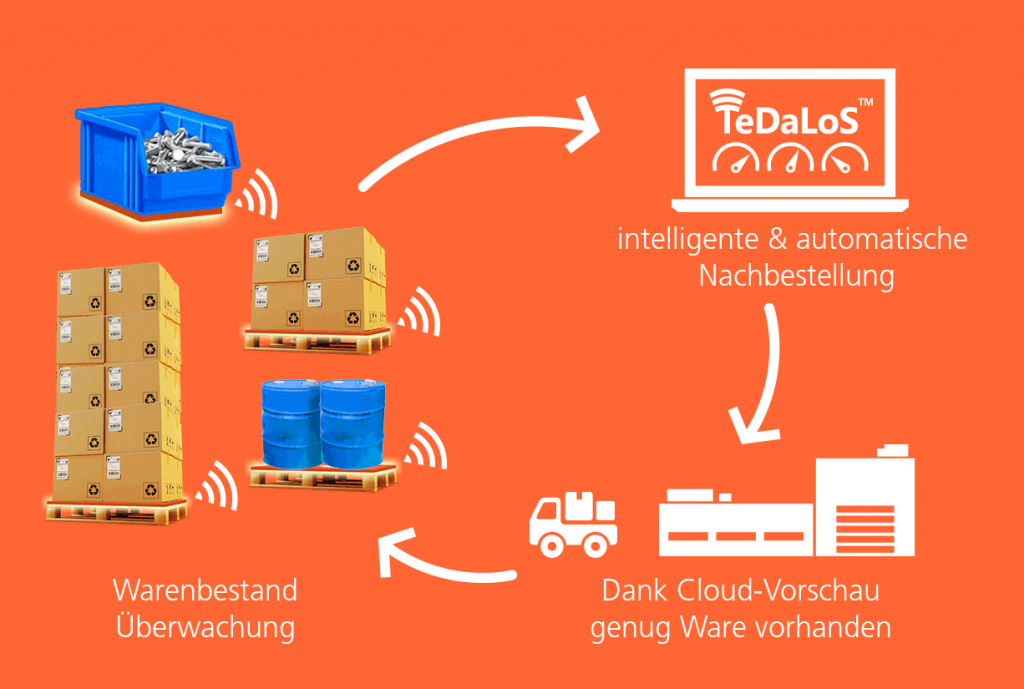

The SaaS (Software as a Service) platform connects smart automation technology and IoT devices with your employees and materials management. TeDaLoS as a bridge between the analog warehouse and your digital material mnagement system.

- ideal for INTERNAL USE, corporate consumers, to keep track of items not managed by your IT-system

- necessary for INDUSTRIAL SUPPLIERS to offer their customers simple and quick-to-implement replenishment solutions

- the way for SENSOR and SYSTEM MANUFACTURERS to offer cloud-based end2end solutions for stock level and material flow monitoring.

SMART PROCESS

Our end-to-end systems take smart decisions. The combination of autonomous measurement technology/sensors and cloud system provides information about your stock levels, triggers your reorders and provides information about the functional status of the sensors and devices used. TeDaLoS increasingly adds dynamic demand forecasts and cross-material consumption pattern recognition. TeDaLoS improves transparency and efficiency without long-term ties, investment, restricted mobility, process changes or any elaborate integration in IT systems.

QUANTITY

Goods inspection right across the site based on stock level and consumption.

DEMAND

Automatically report demand for replenishment or collection, anticipate requirements.

CONTROL

Monitor technology function and add value through additional data such as temperature and location.

VERSATILE APPLICATION

TeDaLoS connects the growing variety of sensors and Kanban systems with the cloud-based, GDPR-compliant platform, which provides industrial suppliers and industry with comprehensive real-time data for optimized warehouse and replenishment processes. The technology enables proactive replenishment control.

Modern technologies and sensors not only determine the number of packaging units in your warehouse, they also allow you to determine the content quantity of each individual package and thus keep an eye on consumption in real time.

The up-to-date information on actual stock levels and demands automates your processes. This enables you to achieve efficiency gains in terms of personnel, freight effort, storage space and tied-up capital, as well as customer relations for replenishment service concepts.

WIRELESS & AUTONOMOUS

The TeDaLoS system is easy to use and requires no special training. The software platform can be used stand-alone or connected to your IT system in various stages.

The independent, open software platform makes it easy to utilize the rapid growth and change in IoT technology for warehouse management in companies and stay future-proof.

The business logic lies within the platform and serves as a translator between the selected technology for stock level tracking and your ERP system or your supply chain partners. This allows you to remain independent of device manufacturers and centralize technology and replenishment services.

Interested?

We would be pleased to make an appointment to introduce you to our product and our software in person.

IN REAL-TIME

Every business strives for greater efficiency, greater reliability of supply and the reduction of risk. Using our system, you can achieve these objectives in your inventory management system, and you will also receive information about material movements right up to point of use – in real-time! This enables you to avoid the usual hurdles of technical systems within your business and in collaboration with suppliers, i.e. long lead times, technical risks, inflexibility and obligation.

WHITELABEL + CUSTOMIZATION

The one-stop solution consists of cloud software that understands a wide range of data protocols and device logic – whether sensors, RFID, vending machines or combined technology. Wireless standards and systems can also be managed via TeDaLoS.

By adapting to your corporate brand, you can manage your management services and technology centrally. You can give your customers immediate online access to the platform in your company layout.

A growing number of leading manufacturers of automation technology are building their solutions on the TeDaLoS platform to integrate their measuring and capturing technology and quickly start marketing of their complete end-to-end solution. Partners are using and marketing the platform in their corporate brand, party with customization to uniquely fit to their hardware feature.

1.

Faster in operation

Can be used without training, installation, scanner or assembly!

2.

Faster adaptation

Flexible in the choice of location or selected technology, adapts to circumstances!

3.

Faster to results

No lead time, no binding to a single supplier and no investment required!